GLASS IN SUSTAINABLE BUILDINGS

As new construction becomes increasingly energy efficient, energy consumption is no longer the only criteria that is being considered when evaluating the sustainable performance of buildings. Based on a complete life-cycle approach, the impact of manufacturing the building materials, as well as the construction, transportation, demolition and end-of-life phases, becomes critical to improving a building’s overall sustainable performance.

Glass is an inert and irreplaceable material that brings natural light in buildings: flat glass production from energy efficient furnaces makes it a product of choice for sustainable buildings.

For instance, the total CO2 equivalent emitted by the manufacturing of an energy efficient double-glazing unit is offset on average within 6 to 20 months[1] by the energy savings realised compared to the same building equipped with inefficient glazing. In addition, glass is mainly made of abundant raw materials such as sand, its manufacturing process is energy efficient, requires low levels of water and generates little waste (broken glass, cullet) that can be easily re-introduced in close-loop in the furnace. In fact, today approximately 26% of the materials’ input that goes into European flat glass furnaces is cullet.

The vast majority of glass products for buildings could be recyclable at the end of their lives. This contributes to even lower environmental impact. When recycled in new glass products, glass waste helps to save both raw materials and energy in manufacturing new glass products.

[1]2050: Flat glass in a Climate-Neutral Europe

Find out more about glass in sustainable buildings in the below Q&A and exemplary glass buildings

Q&A on glass in sustainable buildings

With the right choice of glazing for each building, one can design and construct buildings with as much glazing surface as desired to achieve minimal CO2 emissions generated by the heating and cooling of buildings (the operational carbon emissions). In other words, glazing is no hurdle to highly energy efficient buildings.

The energy efficiency of a building, and its operational emissions, depend on the balance between the energy losses (managed through thermal insulation, airtightness…) and the energy intake (from solar gain). Parameters such as the glazing characteristics, the façade materials the insulation of the envelope (roof, walls and windows) but also the building’s design and its geographic location[1] have a direct influence on the energy efficiency and the operational carbon emissions. Envelope design and products selection are therefore key choices to ensure that a building can limit its CO2 emissions.

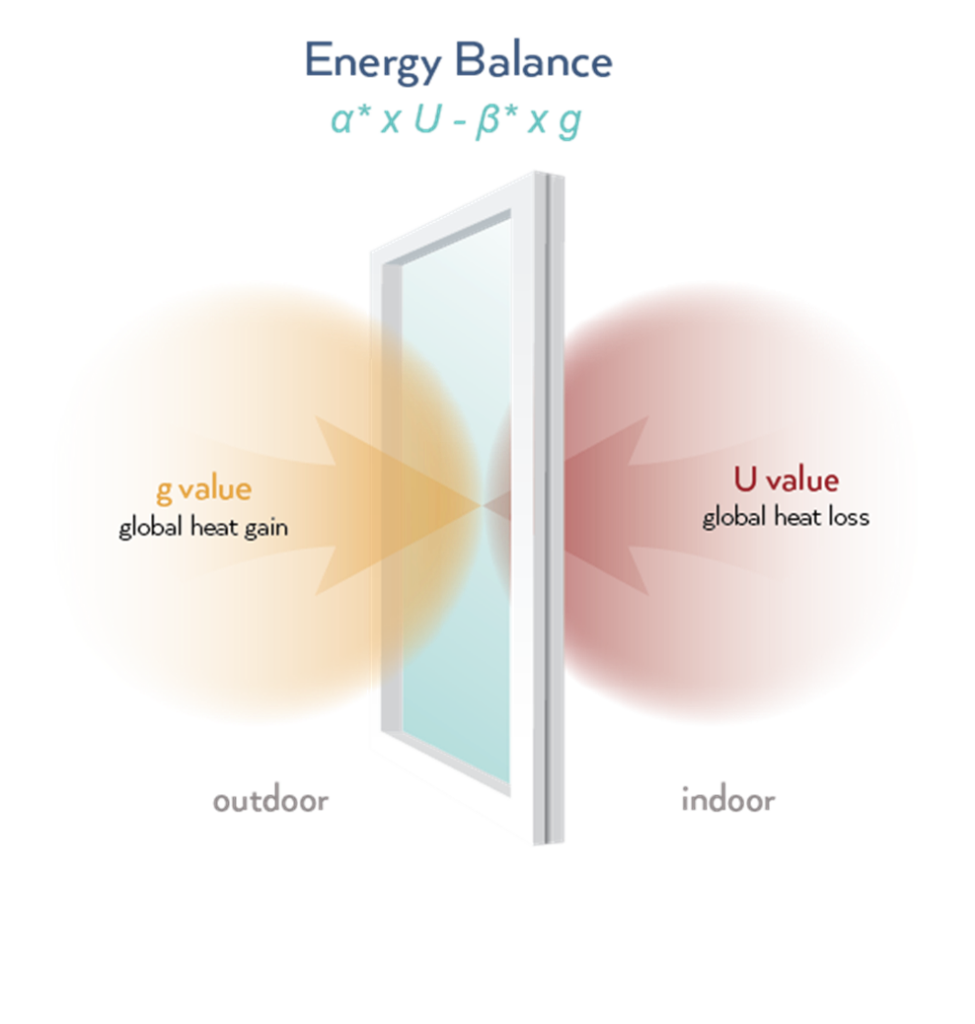

Key glazing parameters such as the thermal insulation (expressed by the U value) and the solar heat capturing or repealing properties (expressed by the g value) must be considered to choose the optimal type of glazing. In addition, the orientation of the façade must also be carefully assessed to allow for an optimized configuration which contributes to maximizing or minimizing solar gains and further reducing the total energy demand. Finding the right surface of glass for façades from an operational emissions perspective is related to finding the right balance between solar gains/protection and thermal insulation needs.

For example, in cool climates, high-performance glazing will help bringing in free solar radiation and keeping in the heat[2]. By contrast, in hot climates where the need for cooling technologies is higher, it is preferable to rely on solar control glazing which proves effective in reducing the solar heat load while still providing natural light and external outdoors views.

For example, in cool climates, high-performance glazing will help bringing in free solar radiation and keeping in the heat[2]. By contrast, in hot climates where the need for cooling technologies is higher, it is preferable to rely on solar control glazing which proves effective in reducing the solar heat load while still providing natural light and external outdoors views.

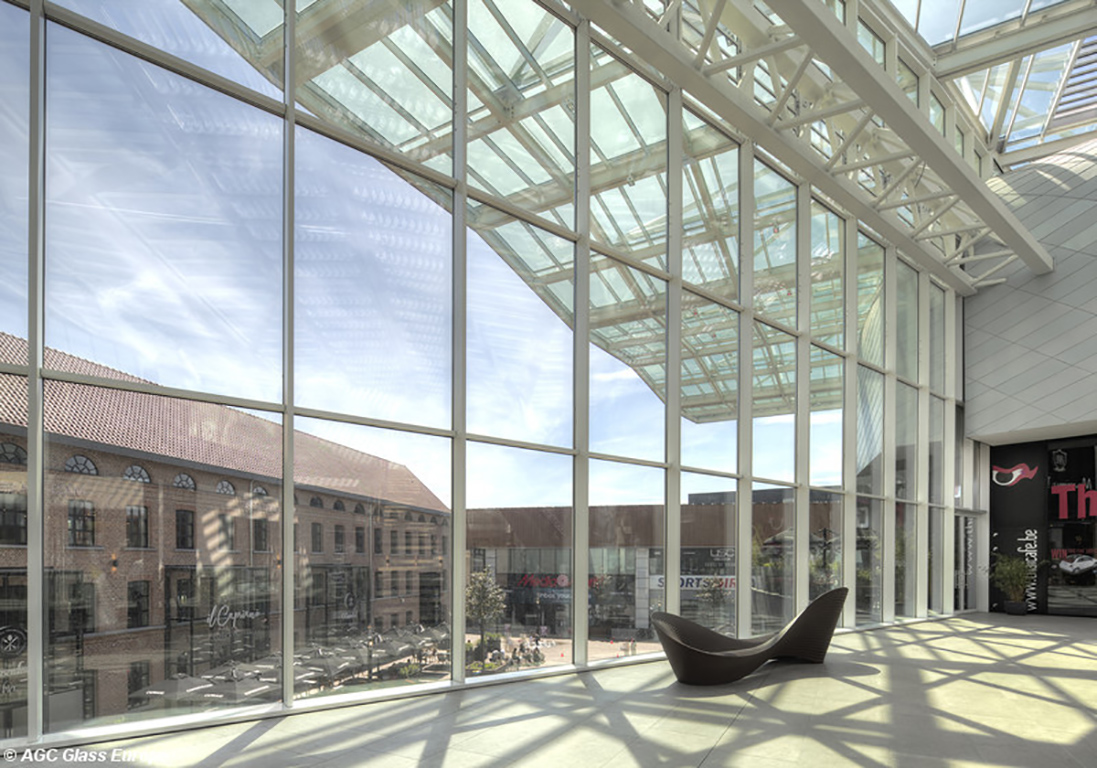

There is a lot of variety and high-performance glazing to choose from which offers freedom to building designers to conceive highly efficient buildings with glass. Opaque façade technologies have great thermal insulation and airtightness properties as well, yet they do not offer the aesthetic appeal and natural daylighting benefits that state-of-the-art glazed surface brings. By providing greater access to natural daylight, highly glazed buildings strongly decrease the need for artificial lighting, also responsible for a part of the buildings’ energy consumption, in addition to contributing to occupants’ wellbeing[3].

Existing sustainable certifications for buildings take into consideration the key parameters mentioned above but also recognise the necessity to have an assessment for each individual project. As such, they do not prescribe nor suggest any ideal glazed surface ratio[4]. The academic literature confirms that it depends on too many building–specific parameters: building location, orientation of the façades, other construction materials, etc.[5]

It is possible to achieve very low operational carbon emissions thanks to the use of advanced glazing technologies. One can think about dynamic glazing, building-integrated photovoltaics (BIPV) shadings, energy efficient spandrels with a glazed front, etc. A project such as “The Curv” demonstrates that a 60-storey highly glazed building[6] can be aligned with the passive house standards[7] if adequate design decisions are taken in concomitance with the aesthetical choices of architects, clients, etc. Many other examples of high energy-efficient buildings largely made of glass exist throughout Europe with some examples provided in this webpage.

[1] To obtain an overview of how the combination of all these parameters impacts the operational emissions of a building, see the following case studies:

Premrov, M., Žigart, M., & Leskovar, V. Ž. (2018). Influence of the building shape on the energy performance of timber-glass buildings located in warm climatic regions. Energy, 149, 496-504. https://doi.org/10.1016/j.energy.2015.05.027

Feehan, A., Nagpal, H., Marvuglia, A., & Gallagher, J. (2021). Adopting an integrated building energy simulation and life cycle assessment framework for the optimisation of facades and fenestration in building envelopes. Journal of Building Engineering, 43, 103138. https://doi.org/10.1016/j.jobe.2021.103138

[2] https://thecurv.ca/

[3] Active for more comfort: Passive House Information for property developers, contractors and clients (2018), Third Edition, https://passivehouse-international.org/upload/Passive_House_Active_for_more_comfort_brochure.pdf

[4] Council, U. G. B. (2014). LEED v4 for building design and construction. USGBC Inc.

Dutch Green Building Council, Breeam NL. (2014). BREEAM-NL 2014 Label for Sustainable Real Estate. https://www.breeam.nl/english-9

[5] See the following research for the optimum WWR from an operational carbon perspective, studying various building models in various climatic zone:

Susorova, I., Tabibzadeh, M., Rahman, A., Clack, H. L., & Elnimeiri, M. (2013). The effect of geometry factors on fenestration energy performance and energy savings in office buildings. Energy and Buildings, 57, 6-13.

Leskovar, V. Ž., & Premrov, M. (2011). An approach in architectural design of energy-efficient timber buildings with a focus on the optimal glazing size in the south-oriented façade. Energy and Buildings, 43(12), 3410-3418.

[6] CURV in Vancouver, which construction shall be achieved in 2027, and will be the world’s tallest passive house building while being highly glazed

[7] Passive Houses allow for space heating and cooling related energy savings of up to 90% compared with typical building stock and over 75% compared to average new builds, https://passiv.de/en/02_informations/01_whatisapassivehouse/01_whatisapassivehouse.htm.

To go further

a) What about the CO2 impact throughout the building’s whole life cycle?

The CO2 emissions of a building come from both the operational carbon (emitted over the lifetime use of the building) and the embodied carbon released during the extraction, manufacturing, transport, installation, and replacement of building components and materials. The whole life carbon of a building is the addition of the embodied and operational carbon. Therefore, to assess the overall whole life-cycle impact of the building, it is critical to consider both operational and embodied carbon [1].

In the coming years, whole life-cycle carbon is meant to decrease as buildings become more and more energy-efficient (helping to reduce operational carbon). Embodied carbon will therefore grow in importance proportionally however it will reduce as well with the increase usage of lower carbon construction products and glazing.

Source: Image from Carbon Cure, ‘What is embodied carbon?’ published 22.09.2020. The image should also mention that end-of-life emissions are included in the embodied carbon.

Source: Image from Carbon Cure, ‘What is embodied carbon?’ published 22.09.2020. The image should also mention that end-of-life emissions are included in the embodied carbon.

[1]ARUP, Saint-Gobain (2022). Carbon footprint of façades: significance of glass. https://www.arup.com/perspectives/publications/research/section/carbon-footprint-of-facades-significance-of-glass#

b) Can glass buildings be energy efficient enough to minimise heating consumption in winter?

Yes, the heating consumption can be limited thanks to the use of high-performance glazing which will allow for high solar gain, making the inside of the building comfortable for its occupants, and reduce the heat loss to the minimum. The lower the glazing U-value, the lower the thermal transmittance and the more insulation the glazing provides.

c) Can buildings with large areas of glazing minimise cooling needs during summer?

Yes, a large area of glazing does not necessarily lead to overheating in the summer. If parameters such as building design are important to avoid too much heat, solar control glazing can reduce the heat load and therefore the need for air-conditioning. According to the TNO institute, the energy consumption used to cool buildings in the EU could be reduced by over 27% in 2050 by using high-performance solar control glazing[1]. Additionally, other innovative technologies such as dynamic glazing (which can tint itself to adapt to varying light conditions) or building integrated photovoltaics with shading devices can minimise heating needs while generating renewable energy.

[1] Bakker, L. (2019). Potential impact of high performance glazing on energy and CO2 savings in Europe. Delft: TNO.

d) Is it necessary to reduce the area of glazing in building facades to make them energy efficient?

Not necessarily. With the right choice of glazing and construction techniques, minimal energy consumption can be achieved independently of the size of glazing.

The energy efficiency of a building depends on various parameters such as glazing characteristics, façade materials and airtightness, building design and geographic location (see Q1 for more details). Consequently, there is no “ideal” area of glazing which is valid for all buildings[1] nor there is a need to decrease glazing size to improve in energy performance.

[1] See, e.g., Premrov et al. (2018), Feehan et al. (2021)

e) Are there still innovation potentials to improve the performance of glass and make new glass buildings more efficient?

The flat glass industry continuously works on improving its manufacturing techniques and developing new energy efficient solutions. The thermal transmittance of insulating glass units has been constantly improving over the years. New technologies such as dynamic glazing with optimised g-value to reduce cooling needs[1] or vacuum glazing to enhance insulation and reduce thickness[2] are constantly being developed to continue providing higher energy performance glazing.

The below graph shows the evolution in glazing performance over the last decades. The Ug value that specifically refers to the glazing performance has been constantly decreasing, which highlights lower heat losses through glazing.

[1] Casini, M. (2018). Active dynamic windows for buildings: A review. Renewable Energy, 119, 923-934. https://doi.org/10.1016/j.renene.2017.12.049

[2] Cuce, E., & Cuce, P. M. (2016). Vacuum glazing for highly insulating windows: Recent developments and future prospects. Renewable and Sustainable Energy Reviews, 54, 1345-1357. https://doi.org/10.1016/j.rser.2015.10.134

If glass as a material contributes to the embodied carbon of façades, meaning the carbon released during the extraction, manufacturing, transport, installation, replacement and end-of-life, glazing “has a lower embodied carbon than opaque build up” depending on the materials selected[1].

The industry was able to decrease by 40% the CO2 emissions per tonne of glass between 1990 and 2018[2]. Currently CO2 emissions generated by flat glass manufacturing derive from the use of natural gas (at 75%) and raw materials carbonates (at 25%). However, thanks to highly optimized energy efficient manufacturing processes, the increased use of cullet, i.e. recycled glass instead of raw materials, the use of more electricity and new technologies, the reduction of CO2 emissions in glass manufacturing continues to decrease so that the industry provides glass products with lower embodied carbon.

As an energy-intensive industry, further reducing the emissions of glass production entails electrifying some parts of the process and/or switching to energy sources such as biogas or hydrogen. This only works providing that new energy sources can be generated with less carbon and distributed in adequate quantity at reasonable costs. Another key aspect resides in increasing the use of cullet as raw material to decrease the melting temperature and thus the CO2 emissions related to melting. To obtain comparable data (between all products) on the embodied carbon of construction products, one should consider the Environmental Product Declarations (EPDs) made available per product according to relevant standards such as EN 15804 and EN 17074.

Furthermore, as indicated in question 1, high-performance glazing has a direct impact on reducing the CO2 emissions during a building’s lifetime. It can help save more CO2 than the emissions emitted by its manufacturing. Depending on the glazing characteristics and the geographic location, this carbon payback time is between 1 to 10 years[3], well below a glazing lifetime of 30 years[4]. This is why CO2 emissions should be considered throughout the building life cycle to balance the embedded emissions with operational ones.

[1] See ARUP & Saint-Gobain (2022)

[2] Glass for Europe. (2020). 2050 | Flat Glass in Climate-Neutral Europe. https://glassforeurope.com/2050-flat-glass-in-a-climate-neutral-europe/

[3] Glass for Europe has made its calculation based on the model developed for the European Commission in LOT32 / Ecodesign of Window Products (see ref.) applying to a single-family house combining heating and cooling performance in north, central and south Europe climatic zones. Space heating and cooling energy mix are based on data provided in the EU reference Scenario 2016: Energy, transport and GHG emissions trends to 2050.

[4] As indicated in the Glass in Building standard (EN 17074)

To go further

a) What about the CO2 impact throughout the building’s whole life cycle?

The CO2 emissions of a building come from both the operational carbon (emitted over the lifetime use of the building) and the embodied carbon released during the extraction, manufacturing, transport, installation, and replacement of building components and materials. The whole life carbon of a building is the addition of the embodied and operational carbon. Therefore, to assess the overall whole life-cycle impact of the building, it is critical to consider both operational and embodied carbon [1].

In the coming years, whole life-cycle carbon is meant to decrease as buildings become more and more energy-efficient (helping to reduce operational carbon). Embodied carbon will therefore grow in importance proportionally however it will reduce as well with the increase usage of lower carbon construction products and glazing.

Source: Image from Carbon Cure, ‘What is embodied carbon?’ published 22.09.2020. The image should also mention that end-of-life emissions are included in the embodied carbon.

Source: Image from Carbon Cure, ‘What is embodied carbon?’ published 22.09.2020. The image should also mention that end-of-life emissions are included in the embodied carbon.

[1]ARUP, Saint-Gobain (2022). Carbon footprint of façades: significance of glass. https://www.arup.com/perspectives/publications/research/section/carbon-footprint-of-facades-significance-of-glass#

b) Are there low-carbon glass products on the market?

Low(er) carbon glass products are products which embedded carbon is significantly lower than the average of other glass products with similar functionalities. Glass products currently available on the market have a much lower embodied carbon impact than in the past decades, thanks to industry’s efforts to decrease CO2 emissions in glass manufacturing. In addition, glazing solutions with significantly lower embodied carbon than other mainstream construction products are nowadays available for purchase in Europe. The Environmental Product Declaration shows the level of CO2 emissions emitted for its production allowing customers to make well-informed choices when selecting their glazing. In the upcoming years, as the sector pursues its decarbonisation, there may be more differences in CO2 emitted to produce glass, particularly between European-made products and imported ones.

c) Can glass production be decarbonized?

The flat glass industry has decreased by 40% the CO2 emissions per tonne of glass produced between 1990 and 2018 and is currently working towards further energy and carbon efficiency of glass making. If current production techniques are being constantly improved and new technical solutions are being tested, they are not all ready for immediate implementation across all plants. Reducing CO2 emissions from glass production requires electrifying some parts of the process and/or switching to new energy sources such as biogas or hydrogen. It means that this clean energy needs to be available and that proper energy infrastructures are in place, which is not in the glass industry’s control. The decarbonisation of glass production will also be accelerated through incentives to increase the recycling of flat glass going back to flat glass, as energy efficiency of the furnace improves with higher cullet ratios.

Sustainable buildings minimise the energy and natural resources consumption and contribute to the comfort of their occupants in a life-cycle perspective. Several assessments methodology exist such as the LEED or BREEAM certifications.

When looking specifically at the CO2 emissions impacts of a building, all carbon emissions, meaning the embodied carbon released during the extraction, manufacturing, transport, installation, replacement and end-of-life and the operational carbon released by the heating, cooling, and energy use, must be considered. A whole Life cycle assessment (LCA) will likely demonstrate that the use of high-performance glazing and lower carbon glass contribute to the improvement of the building’s sustainability. Depending on the specificities of each project, low(er)-carbon glass and glass coatings are effective ways to improve durability[1] and reduce whole life carbon as they have an improved “return on investment”, for example when compared to external shading and internal blinds[2]. Solar control coatings for instance have minimum embodied carbon compared to the addition of shading solutions (such as internal and external blinds).

However, glazing is not the only factor impacting a building’s life-cycle carbon impact. Giving a general answer regarding all highly glazed buildings is therefore complex. The sustainability of the other construction products, the building design characteristics (such as the walls, roof, structure, floors), its orientation or the thermal performance of construction materials all have a direct impact. The heating, ventilation, and air conditioning systems, though impacted by the choice of glazing, will also play a strong environmental impact.

Overall, it is possible to build a sustainable building minimizing embodied and operational carbon by using important glass surfaces, should all the right parameters be taken into account and a specific attention given to all building elements. The use of glazing does not render a construction or building de facto sustainable neither.

[1] Khaled, K., & Berardi, U. (2021). Current and future coating technologies for architectural glazing applications. Energy and Buildings, 244, 111022. https://doi.org/10.1016/j.enbuild.2021.111022

[2] ARUP & Saint-Gobain (2022) which shows that external shading and internal blinds have a higher embodied carbon than solar control coatings for similar operational carbon.

To go further

a) What about the CO2 impact throughout the building’s whole life cycle?

The CO2 emissions of a building come from both the operational carbon (emitted over the lifetime use of the building) and the embodied carbon released during the extraction, manufacturing, transport, installation, and replacement of building components and materials. The whole life carbon of a building is the addition of the embodied and operational carbon. Therefore, to assess the overall whole life-cycle impact of the building, it is critical to consider both operational and embodied carbon [1].

In the coming years, whole life-cycle carbon is meant to decrease as buildings become more and more energy-efficient (helping to reduce operational carbon). Embodied carbon will therefore grow in importance proportionally however it will reduce as well with the increase usage of lower carbon construction products and glazing.

Source: Image from Carbon Cure, ‘What is embodied carbon?’ published 22.09.2020. The image should also mention that end-of-life emissions are included in the embodied carbon.

Source: Image from Carbon Cure, ‘What is embodied carbon?’ published 22.09.2020. The image should also mention that end-of-life emissions are included in the embodied carbon.

[1]ARUP, Saint-Gobain (2022). Carbon footprint of façades: significance of glass. https://www.arup.com/perspectives/publications/research/section/carbon-footprint-of-facades-significance-of-glass#

b) Is it possible to recycle end-of-life glazing products?

Yes, float glass is an infinitely recyclable material. However, the safety and performance requirements for the final product permit only the use of recycled flat glass of the highest quality. The recycled flat glass that will be used should not be contaminated with other recycled products and waste, this is why proper dismantling and collection of old glazing is critically important to facilitate recycling. To further increase recycling capacities a proper collection and logistics infrastructure needs to be put in place to recuperate flat glass and resend it to flat glass melting ovens, i.e. the higher form of recycling, closed-loop flat glass to flat glass recycling[1]. The industry is actively working on it and increasing the share of recycled content in new products also to use less raw materials and to decrease the embodied CO2 emissions.

[1] See initiatives such as the VRN scheme in the Netherlands: https://www.vlakglasrecycling.nl/

c) Isn’t the sand used to make glass becoming very rare and irresponsibly mined?

No. The glass industry uses a very specific / pure type of sand that is neither rare, nor the type of sand irresponsibly extracted from riverbeds and beaches in some parts of the world. The latter type of sand is not adapted for glass melting.

Silica sand used in flat glass manufacturing is available in the EU in sufficient quantity[1] and is extracted in quarries following to high sustainability standards. These quarries are also regulated by a set of European, national and local legislations. Permission to extract sand is not given without strict requirements for restoration of the workings (including restoration to agricultural land, to forestry or to wildlife reserves) for example. Flat glass manufacturers have strict protocols in place to ensure both the quality of sourced sand and its sustainable mining by their suppliers[2].

[1] European Commission, Directorate-General for Internal Market, Industry, Entrepreneurship and SMEs, (2017). Study on the review of the list of critical raw materials: final report, Publications Office. https://data.europa.eu/doi/10.2873/876644

[2] Glass for Europe (2020). From sand to flat glass. https://glassforeurope.com/wp-content/uploads/2020/05/Sand-GfE-paper-May2020.pdf

d) Is flat glass transportation generating a lot of CO2 emissions?

As flat glass sold in the EU is mostly manufactured and transformed in Europe, it is transported exclusively by trucks and on relatively short distances (Today approximately 5000 semi-trailers are used to transport flat glass in the entire EU and they travel below 600km on average[1]). Compared to glass production, transport represents a minor source of emissions which is likely to be compensated by the CO2 cut high-performance glazing can generate when used in buildings[2]. It remains nevertheless a source of emissions which the industry is working on minimizing by optimizing payloads. European and national initiatives to incentivize decarbonised transportation trucks are supported by the industry.

[1] Glass for Europe (2023). Revision of the Weights & Dimensions Directive – A well-oriented first step that can be improved to increase sustainability and logistic efficiency. https://glassforeurope.com/revision-of-the-weights-dimensions-directive/

[2] Glass for Europe evaluated that in the worst-case scenario (long distance made with a disadvantageous scenario for CO2 emissions per km), transporting windows would represent only 2% of the total embodied emissions. More details on these calculations can be given on demand.

e) Since triple-glazed windows generate more CO2 emissions during the production phase than double-glazed windows, is it worth using them?

In most cases yes, since the thermal performance of triple-glazed windows is generally higher than the one of double-glazed windows. The “carbon payback time”, meaning the time needed to offset the emissions emitted during the manufacturing, of an extra layer of glass for the triple glazed window is likely to be shorter than the 30-year lifetime of the window. According to recent simulations realised by Glass for Europe, the payback time is ~17 years in central Europe and ~14 years in northern European climates[1]. This data is purely indicative and solely for the products, building configurations and energy performance methods analysed. For southernmost climates, the use of solar control glazing is likely to be the most crucial factor, rather than the number of panes in the Insulating Glass Unit (IGU). Making a choice between double or triple is very project-specific, considering the building design, location (climate), energy performance, usage, comfort requirements, etc. In some situations, especially in countries with mild / hot climates where residential energy consumption is highly decarbonized, double-glazed windows may be better suited from a CO2 emissions perspective.

[1] Glass for Europe. (2022). Calculations of embodied and operational carbon of double and triple glazed windows. https://glassforeurope.com/positions/building-and-construction/

f) Is glazing lifetime long enough to avoid consuming too many natural resources?

In comparison with other construction materials, glass is lightweight and yet very durable. Standards define the lifetime of glass and insulating glass units as being 30 years but practically glass is rarely changed on its own, it is most likely changed when the windows or the building are retrofitted, which is usually after 50 years. If the lifetime of the building taken as reference is 50 years, then only one upgrade is needed to ensure continued energy-performance and to simulate CO2 whole life-cycle impacts. The main environmental impacts of glass manufacturing are the use of raw materials and energy, as shown in the Environmental Products Declarations.

g) What are the other impacts on the environment that need to be considered when building skyscrapers with a lot of glass?

Some of the main risks to consider are bird collisions, wind tunnels and heat islands.

Clear surfaces in highly glazed buildings can create perceived flythrough conditions for birds and therefore represent a threat. However, so-called “bird friendly glazing” exists and can actually contribute to reduce birds’ collisions with buildings.

Wind tunnels are generated by skyscrapers but are not specific to glazed façades. They are the result of inadequate urban planning. On the contrary, glazing products can be tailor-made to be installed on buildings specifically designed to suppress wind tunnel effects.

Finally, if heat island effects can appear, meaning when urbanized areas experience higher temperatures than outlying areas due to the structures of buildings, roads, and other infrastructures, solutions exist. The design of buildings can be adapted to avoid inadequate concentrations of lights which would bring too much heat. Glass with lower reflectivity or the use of shadings can contribute to drastically reducing this effect.